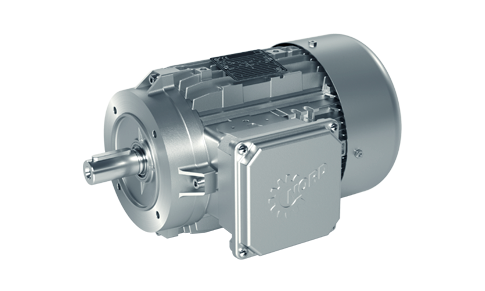

Asynchronous AC electric motors

NORD three-phase electric motors provide a power range from 0.16 to 75 HP and are extremely resistant to electrical and mechanical overload.

- Performance: 0,12 – 55 kW

- Efficiency classes: IE1, IE2, IE3, IE4

- Standard and smooth surface motors

NORD three-phase asynchronous motors – Tough and Versatile

NORD produces four different lines of AC electric motors for operation in a wide variety of applications. While smooth-body motors are ideal for the food & beverage industry, two-speed motors and single phase motors provide the necessary power for machine tools, pumps, conveyor belts or fans.

Our three-phase asynchronous motors provide standard power steps from 0.16 to 75 HP and feature unmatched performance, high quality workmanship and long service life. AC motors can be combined with the full NORD gearbox and drive technology portfolio for a complete solution.

Advantages of our three-phase asynchronous motors:

- Durability

Our standard motors offer unmatched protection against electrical and mechanical overload. - Low Maintenance

Thanks to high quality workmanship and a simple design, maintenance costs are kept to a minimum. - Versatility

NORD three-phase asynchronous motors are suitable for countless applications in a wide range of industries.

Our single phase motors: Simple Design, Reliable Performance

Our single phase motors are available in three versions: For simple applications we recommend the economical single phase motor with a Steinmetz circuit; for more demanding applications, designs with an operating capacitor or an operating and starting capacitor are the best solution.

Single phase motors are available with powers from 0.16 to 2 HP. They can be operated on 50 Hz or 60 Hz frequencies at 115V or 230V and support a wide voltage range (220V to 240V).

Two-Speed motors: One drive, flexible speeds

The NORD motor portfolio includes two-speed motors for a variety of applications which demand flexibility. These drives enable operation with two or more fixed speeds. We supply this type of motor in a 4/2 pole, 8/4 pole, 8/2 pole and 6/4 pole version and if required, with a Dahlander winding.

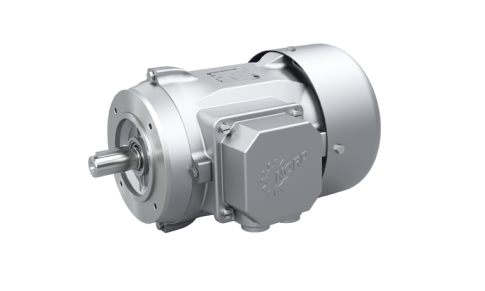

Smooth-body motors for applications where sanitation and cleanliness is essential

NORD three-phase asynchronous motors are also available in a wash-down, smooth surface version. Our smooth-body motors are very easy to clean and are ideal for use in the food and pharmaceutical industries. They are perfectly suited for combination with aluminum NORD inline, right angle bevel and SMI worm gearboxes for a complete washdown solution.

Thanks to their aluminium housing, smooth-body motors are very corrosion-resistant. For harsher environments, they can be optionally supplied with NORD’s NSD tupH Sealed Surface Conversion.

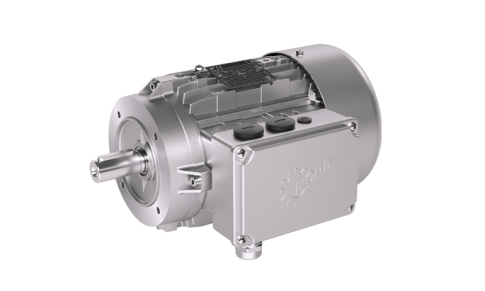

Synchronous Permanent Magnet Motors

Synchronous motors

Our synchronous motors operate extremely efficiently. They are therefore ideal for use in energy-intensive applications such as intralogistics.

- Performance: 0,75 – 5,5 kW

- Standard and smooth motors

- Efficiency classes: IE4

Ultimate efficiency

Synchronous motors from NORD feature exceedingly high efficiency and a very high power density. Thanks to these excellent properties, considerable energy savings can be achieved, especially for continuous duty applications.

NORD IE4 motors are used throughout the world, particularly in intralogistics (e.g. in distribution centers and airports) as well as in pumps, fans, etc.

Our AC motors: High efficiency, low energy consumption

- Efficiency

Our AC motors have a very high efficiency. Unlike commonly used asynchronous motors, this efficiency remains unchanged, even during partial load operation and at low speeds. - High performance

Synchronous motors from NORD DRIVESYSTEMS provide impressive torques and a high overload capacity of up to 300%. - Robust

NORD synchronous motors are available in a washdown version without fan, and if required, they can also be sealed with the highly effective nsd tupH corrosion protection. - Flexible

Due to their high power density, our synchronous motors have a compact design and can therefore be easily installed in confined spaces.

More efficient than mandated: NORD energy saving motors

The extremely efficient operation of NORD AC motors is due to the use of permanent magnets, which eliminate the need for an external energy supply to generate the magnetic field. Thanks to this technology, our IE4 synchronous motors are considerably more efficient than what is currently required by global standards. NORD energy saving motors significantly reduce your operating costs. Investment in these drives often pays for itself within less than two years (ROI).

Would you like to find out more about our high efficiency IE4 motors?

Click here

NORD IE4 motors reduce the number of variants

Due to the use of permanent magnets and excellent heat dissipation, our synchronous motors have a high power density and a higher maximum achievable torque than comparable drives.

Due to their compact design, NORD AC motors can be easily integrated into confined spaces. Thanks to the wide frequency range of our IE4 motors (up to 70 Hz) users can also reduce the number of drive versions which they use.

NORD smooth-body motors Perfectly suited for the food industry

NORD AC motors are not only compact and powerful, they are also easy to clean. Due to its hygienic, easily washable surface, the washdown version, as a smooth motor, is ideally suited for use in the food industry. The corrosion resistant aluminium housing has IP69K enclosure protection and can also be pressure cleaned. If required, we can optionally seal the motors with the innovative nsd tupH surface treatment.

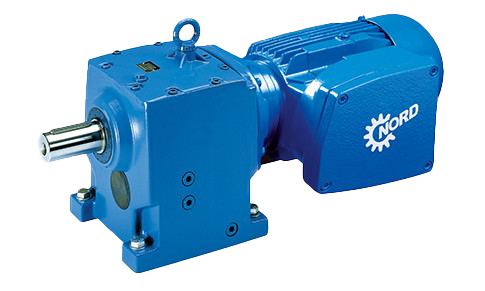

Explosion Proof Motors

Explosion-proof motors

Explosion-proof motors from NORD DRIVESYSTEMS provide powers from 0.16 to 40 HP and meet all of the requirements of the stringent European ATEX directives.

- Performance: 0,12 – 22 kW

- Efficiency classes: IE1, IE2

Electric motors with explosion protection

In explosion hazard areas, systems and components must comply with the appropriate national regulations of the country in which they are operated. Within the EU, this is Directive 2014/34/EU. NORD DRIVESYSTEMS has decades of experience with gas and dust explosion protection and offers particularly robust electric motors with powers from 0.16 to 250 HP especially for this field of use.

In addition to explosion protection requirements, these motors also meet requirements which are not specified for explosion protection, such as Ecodesign, EMC and the RoHS Directive.

In addition to motors for the European market, NORD DRIVESYSTEMS also offers explosion protected motors for many other regions of the world, e.g, the USA or according to the IEC EX standard.

These motors are extensively protected against explosion and are specially constructed for applications in potentially explosive dust or gas atmospheres. Our explosion protected motors are used in a wide variety of applications, e.g to drive pumps, agitators or lifting gear.

Explosion protected motors from NORD: Trust our expertise

- Robust

Our explosion protected motors can be operated in category 2D or 3D dust atmospheres (Zones 21 and 22) as well as in category 2G or 3G gas atmospheres (Zones 1 and 2). - Quality

NORD DRIVESYSTEM works very closely with the Physikalisch-Technischen Bundesanstalt (PTB) and the DEKRA EXAM GmbH to maintain the quality of production, inspection and products at the very highest level. All Category 2 motors have type test certification. - Know-how

NORD DRIVESYSTEMS has many years experience with gas and dust explosion protection and for more than a decade has produced explosion protected motors which meet even the most stringent requirements.

Drives with dust explosion protection

Whether in grain mills, the food industry or the pharmaceutical industry: Explosive dust atmospheres can occur in all of these areas of use. To securely prevent fires or explosions, for use in Europe these motors fulfil the European standard EN 60079-31 and ignition protection class tD

Find out more about the advantages of our electric motors with dust explosion protection.

Explosion protected motors for gas atmospheres

Effective explosion protection is also essential for drive systems in environments with potentially flammable gas atmospheres. Because of this, NORD produces explosion protected motors especially for these areas, which comply with the stringent regulations of EU Directive 2014/34/EU. We offer these drives with ignition protection types “Increased Safety” (e), “Pressure-Resistant Encapsulation” (d/de) and “Non-Sparking Design” (n) in the high efficiency class IE2 for these motors.

For areas in which both dust and gas atmospheres may occur, we will also be glad to supply drives with combined protection.